Products Engineering

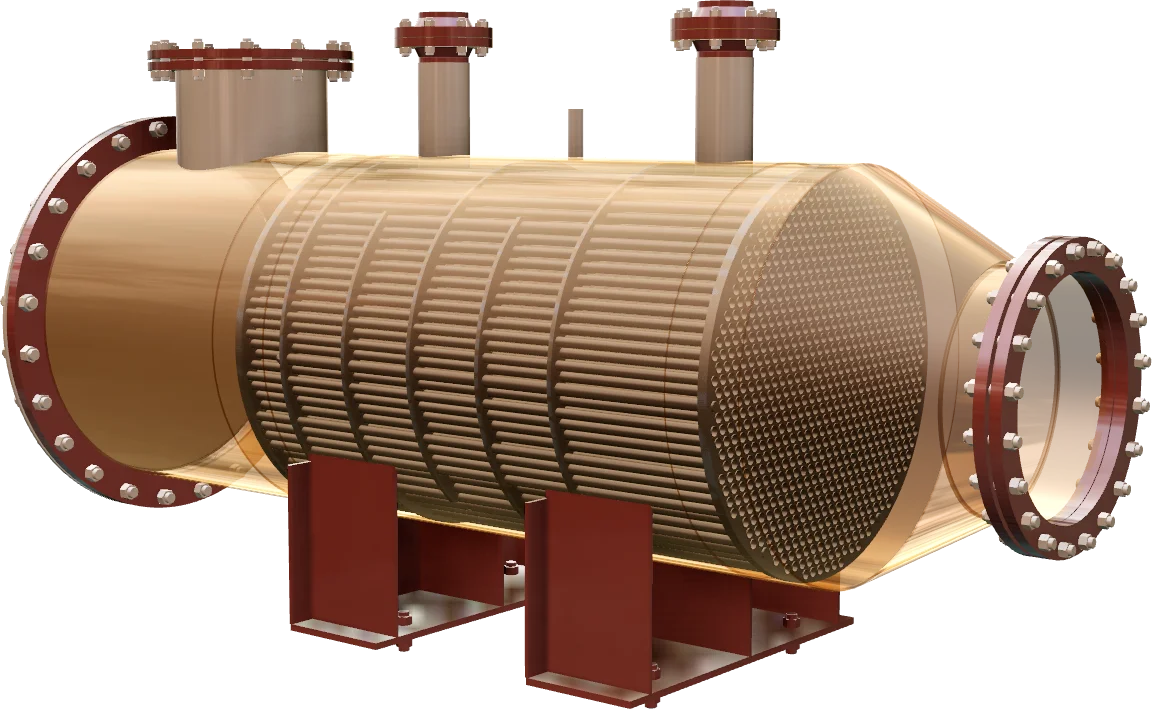

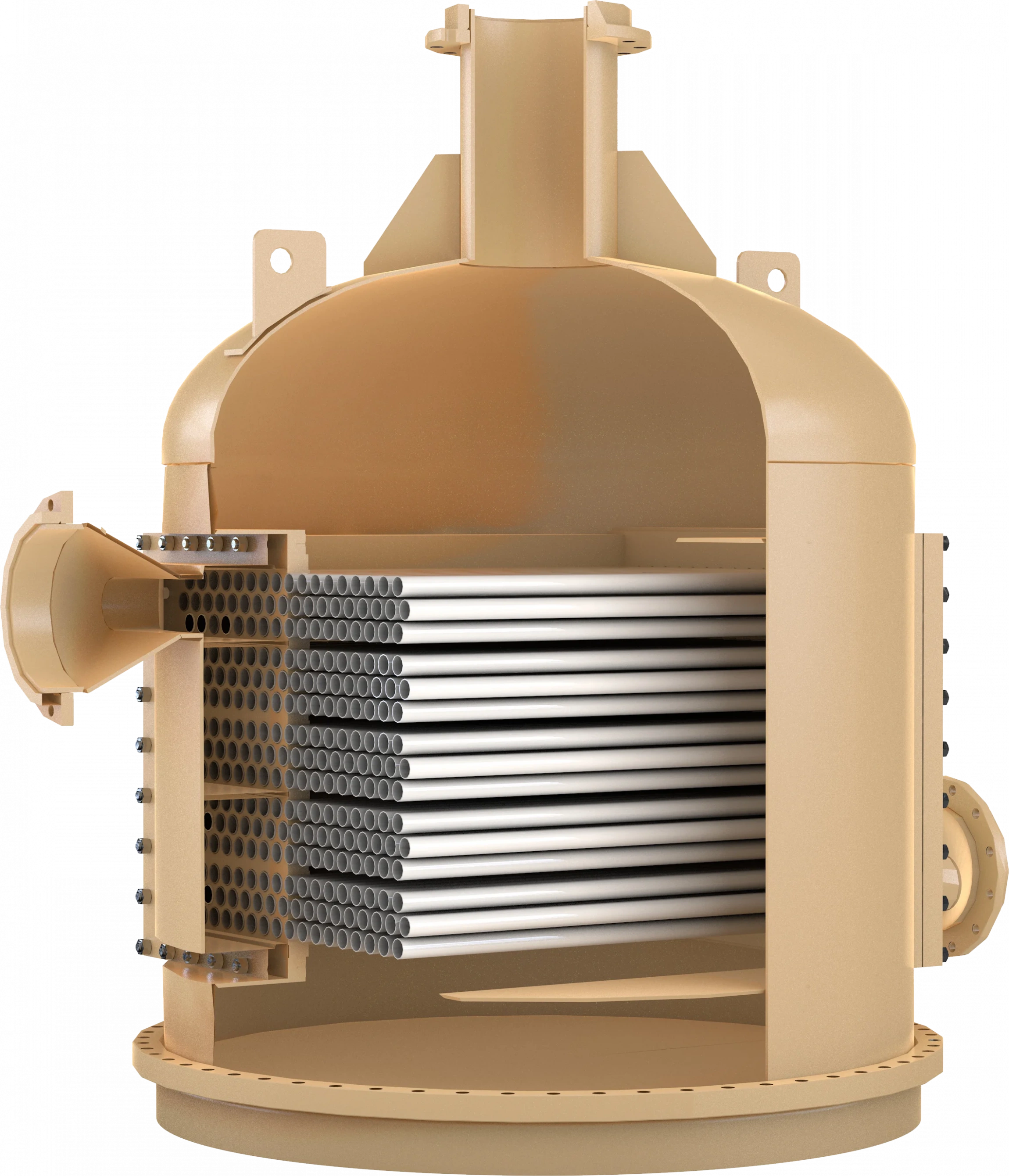

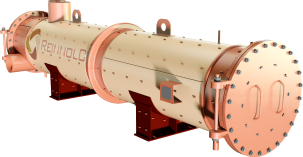

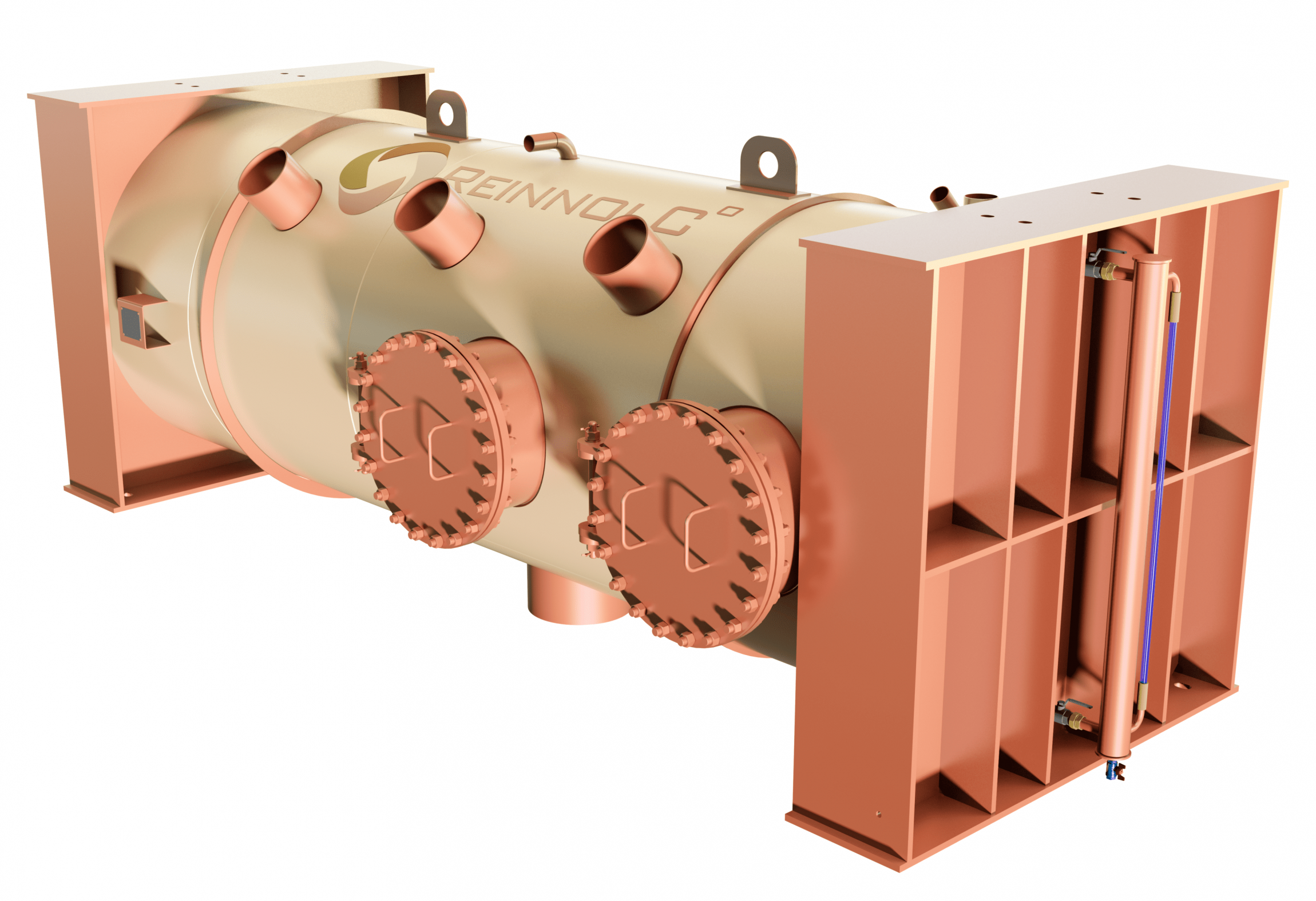

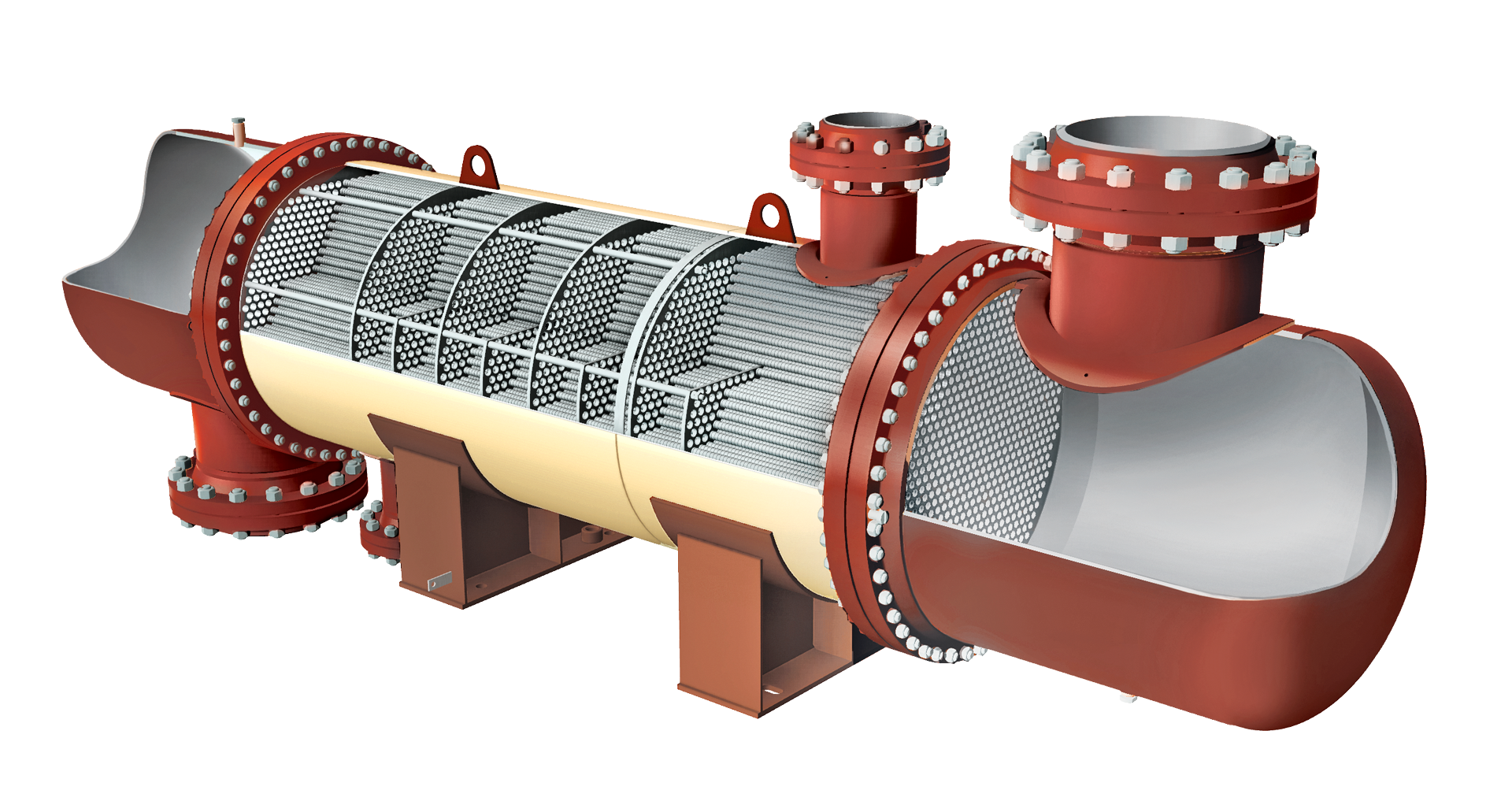

GreenTube WHB Heat recovery steam generator

WHB

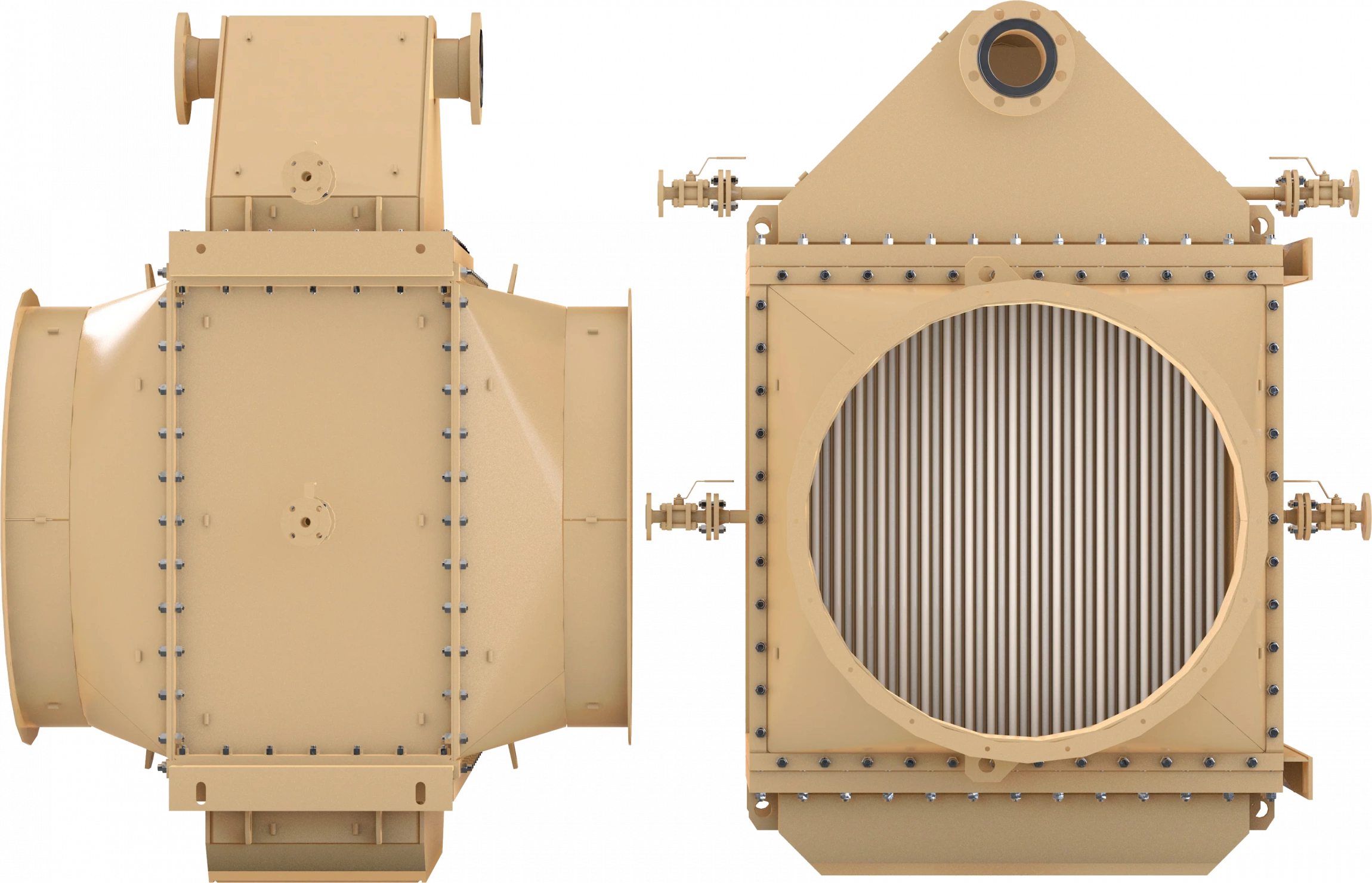

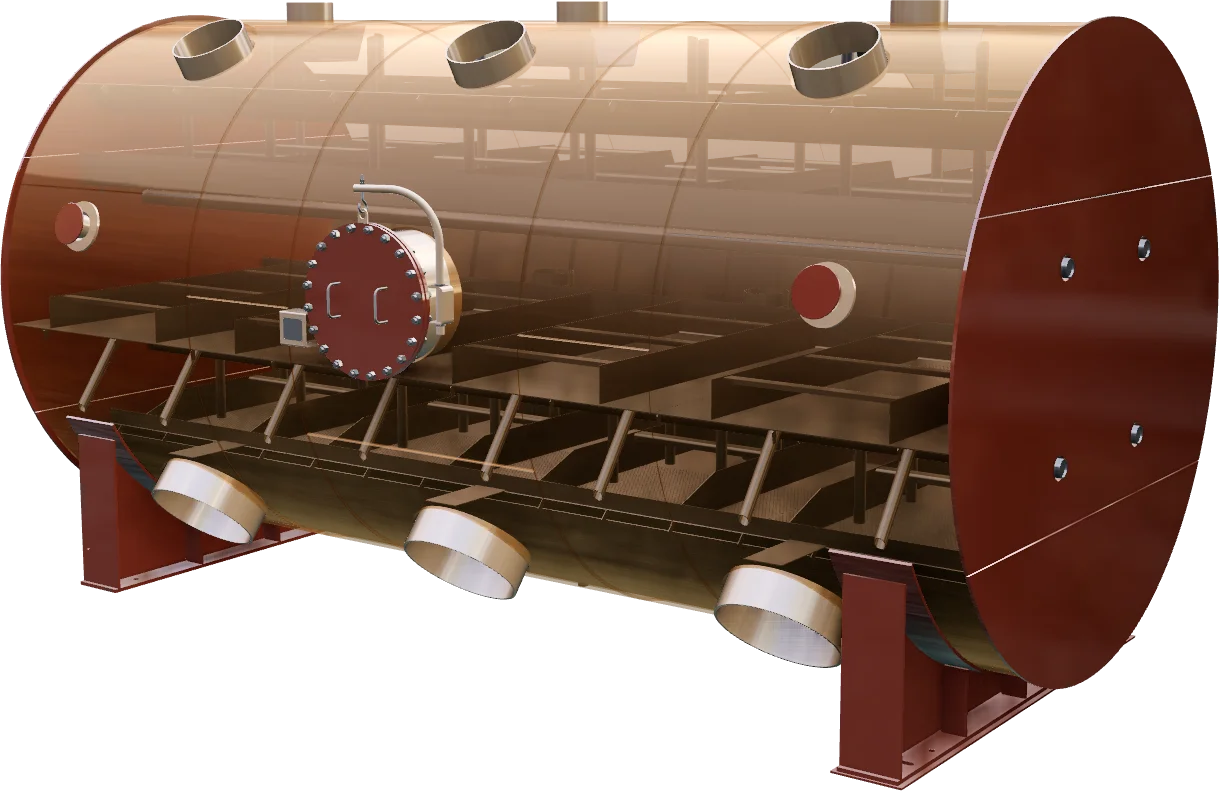

GCU

GreenTube GCU Waste heat recovery unit for the working agent heating unit

GCU

GreenTube GCU Exhaust gas heat recuperator

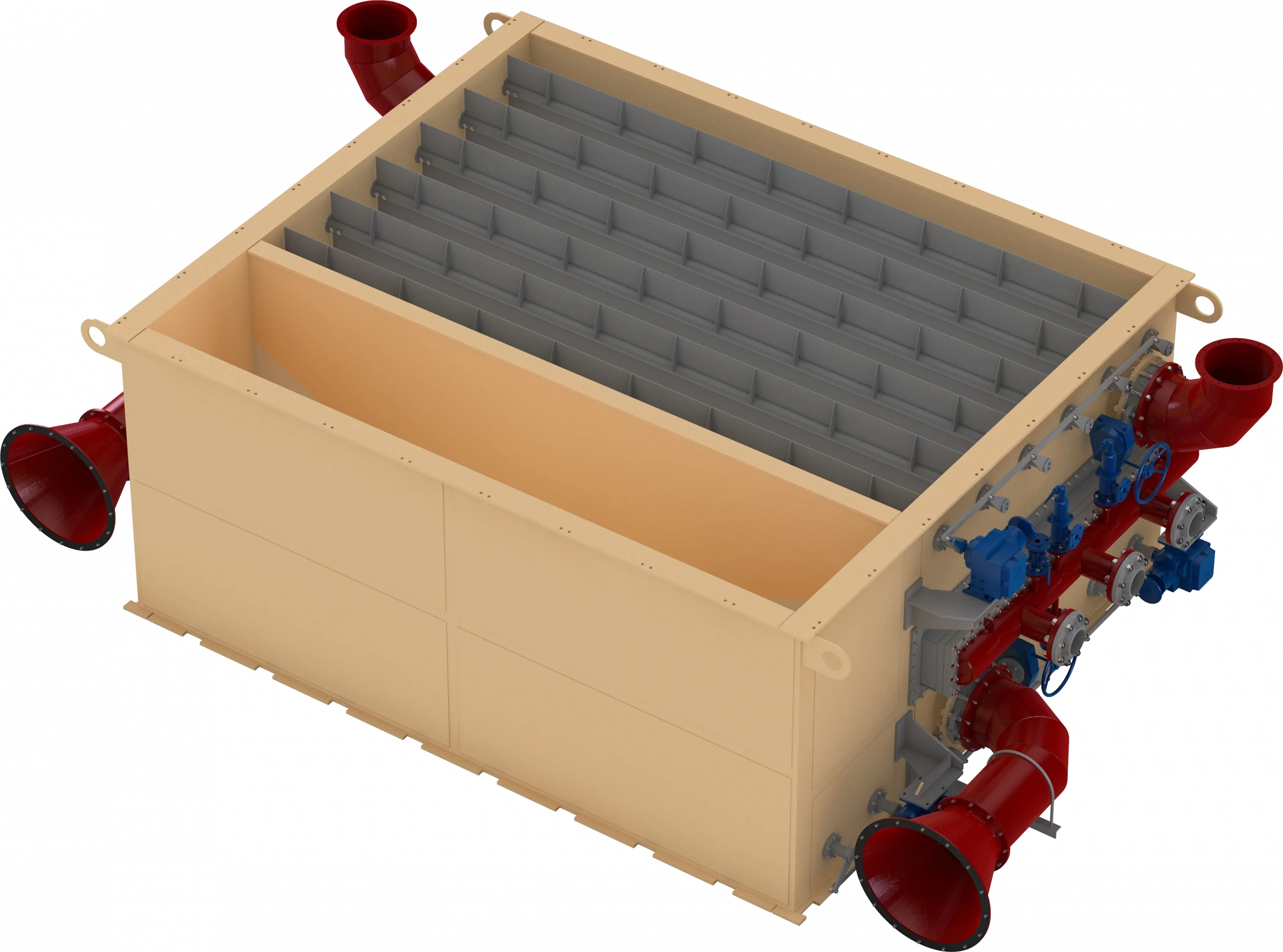

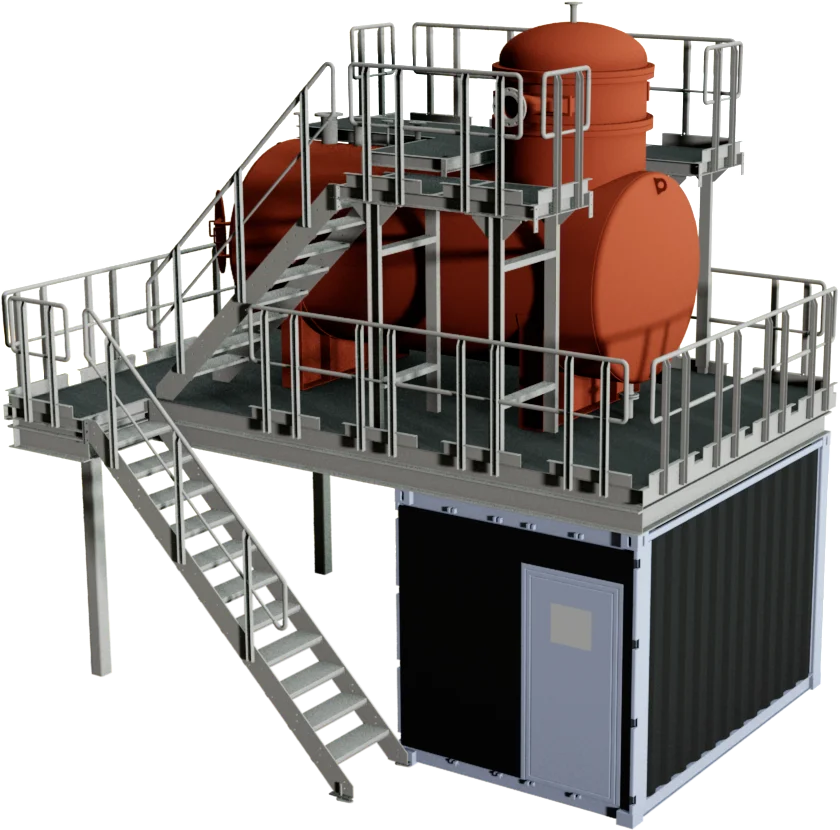

GreenTube Modular solutions

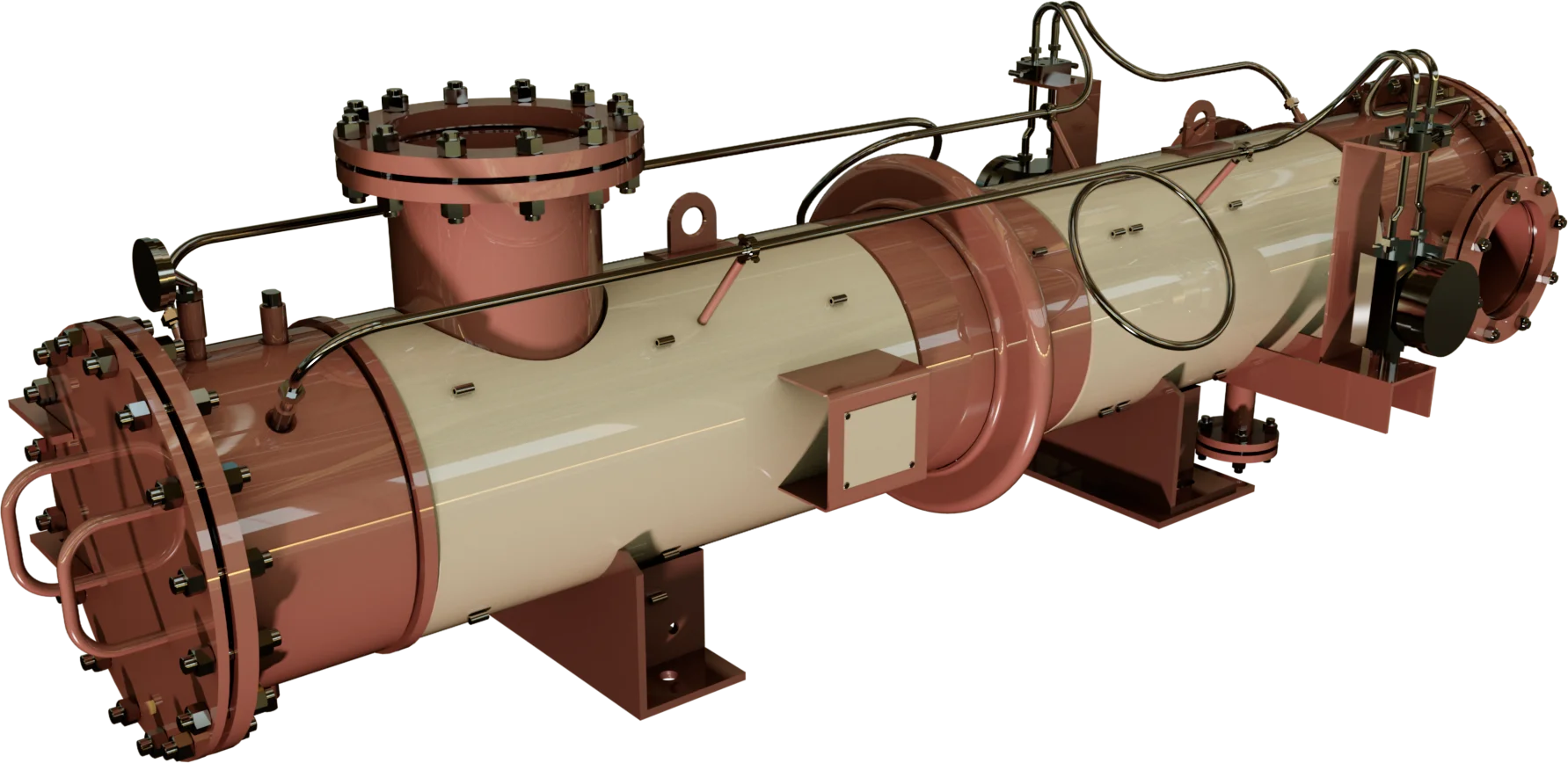

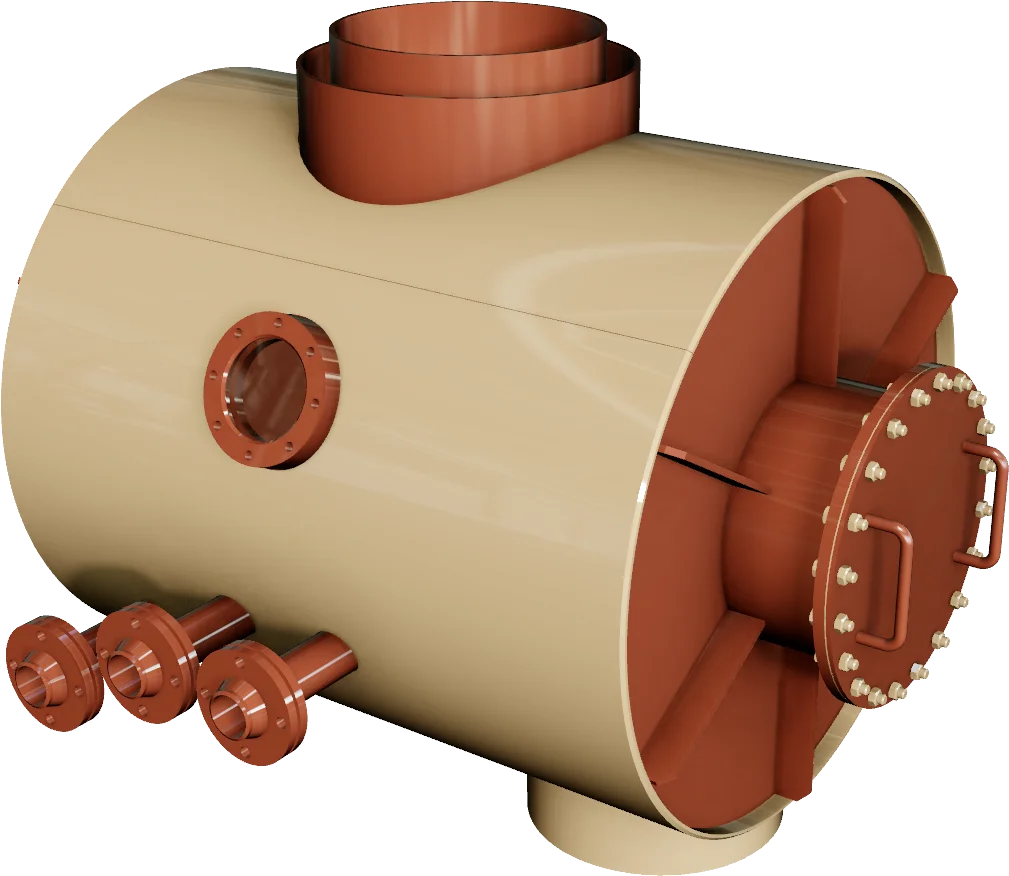

STX-R

GreenTube STX-R Dephlegmator

FVE

Exerger FVE flash evaporator

DeGasExer DV Vacuum deaerator

DK

DeGasExer DK Deaerating condensate collector

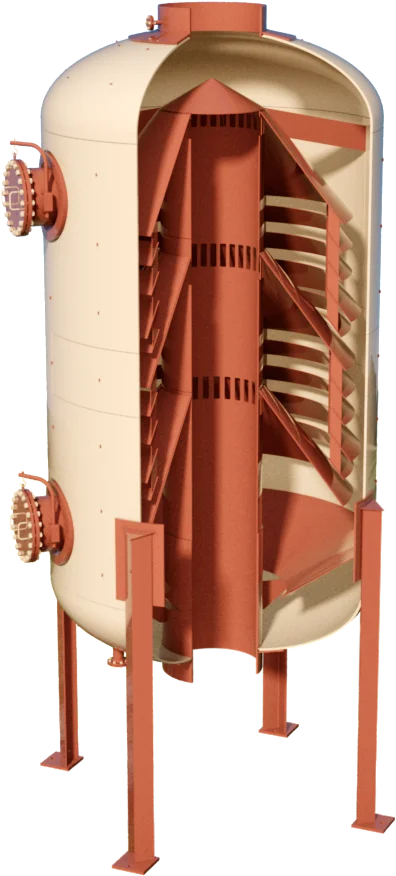

DeGasExer DV Vacuum deaerator

DV

F

GreenVessel F Inertial gravity filter

T

Green Vessel – concentrate collector unit

GreenVessel R Reactor

R

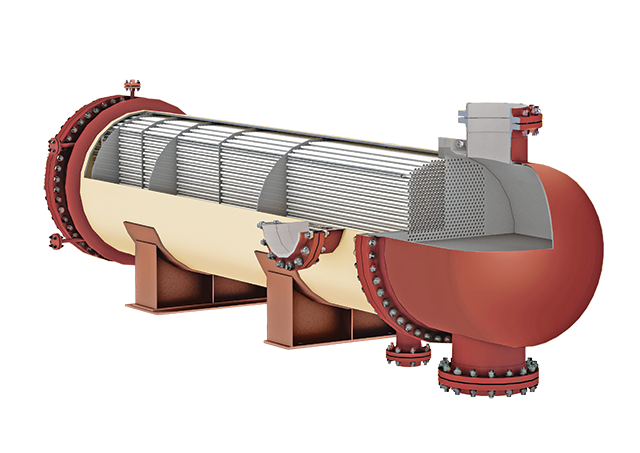

Green Tube

Green Tube heater

Green Vessel

Green Vessel – concentrate collector unit

Technology Engineering

Оборудование ReinnolC для атомной промышленности

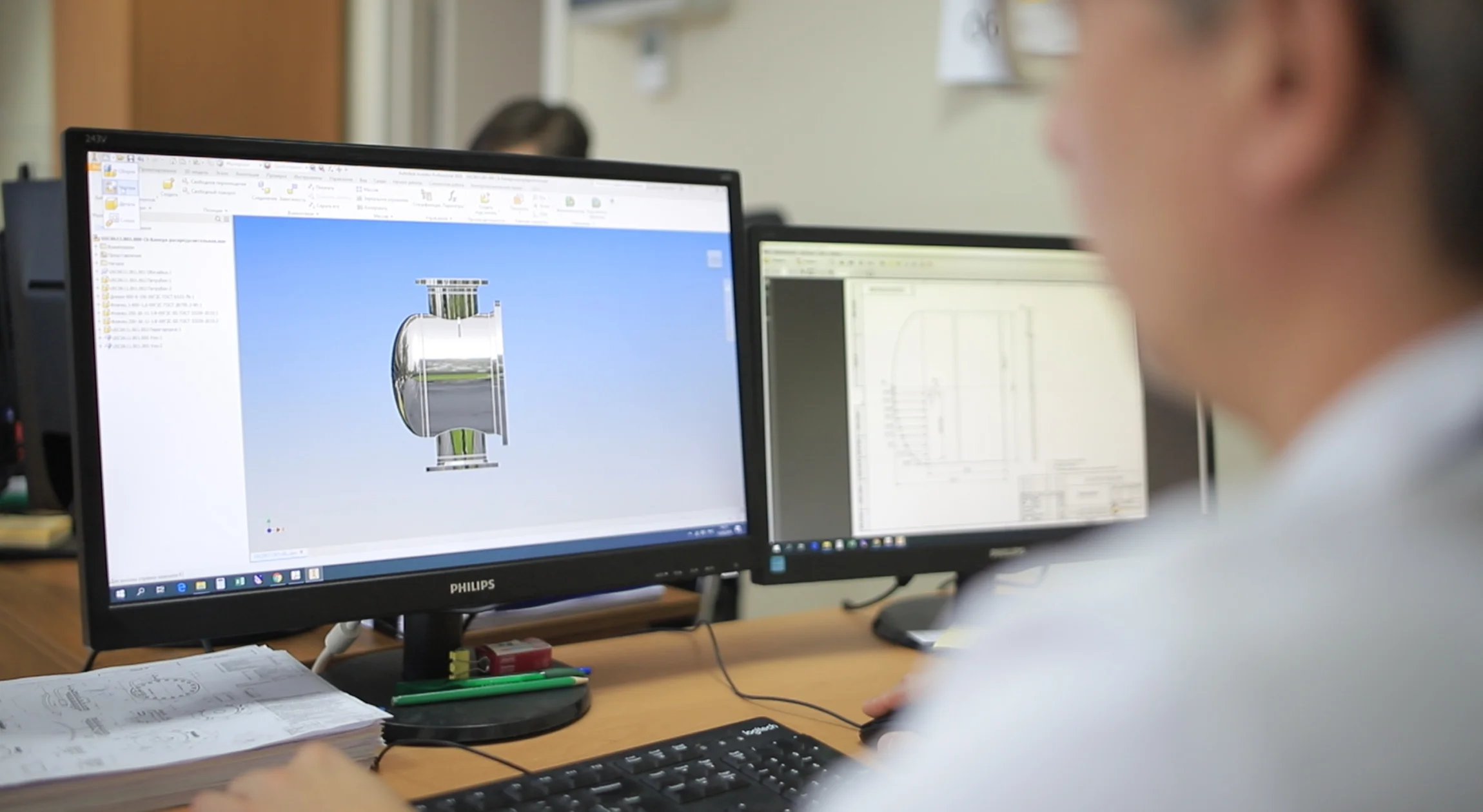

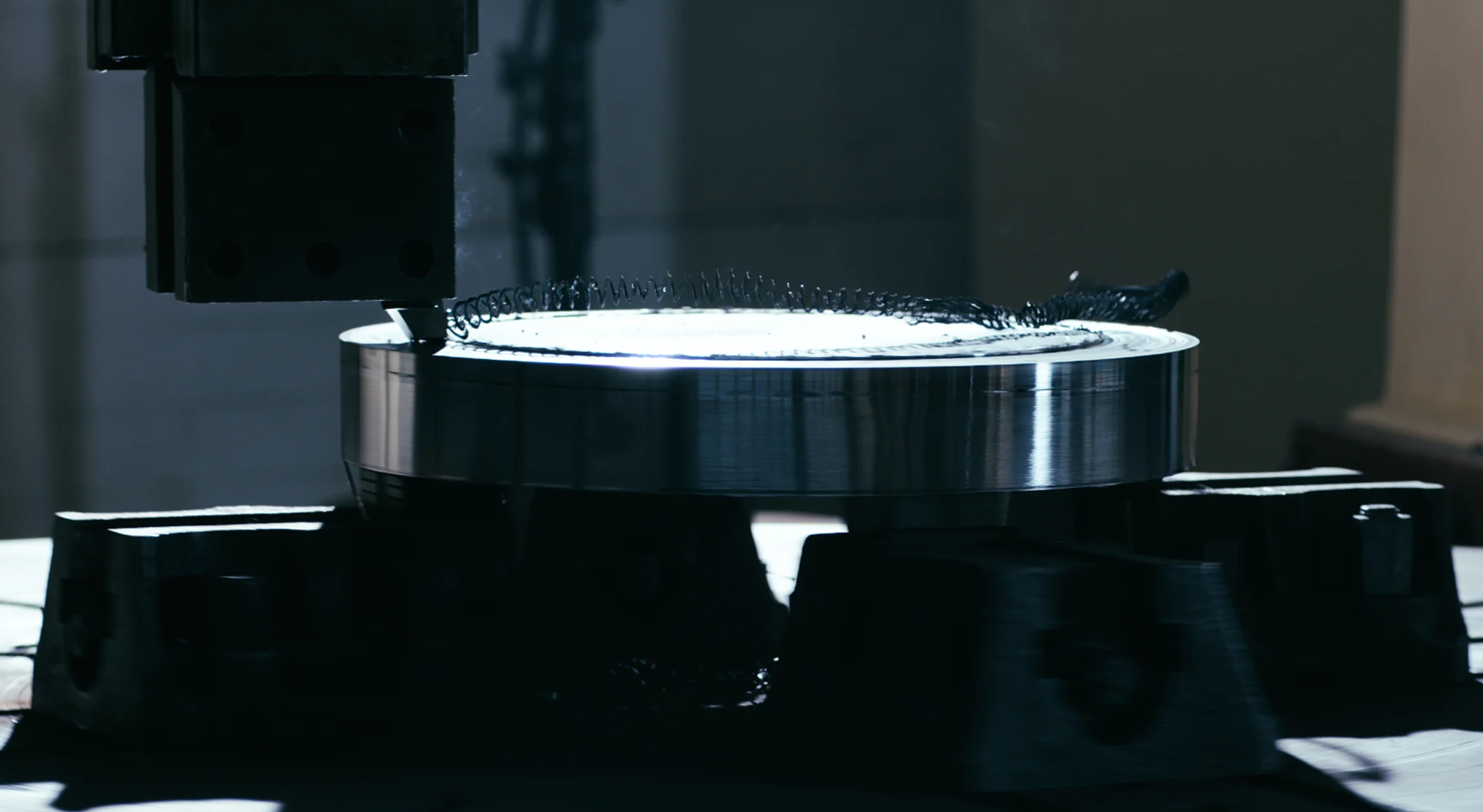

Компания работает по лицензии на конструирование и изготовление оборудования 2 и 3 классов безопасности, участник проекта развития поставщиков Росатома.

Опыт изготовления оборудования для объектов использования атомной энергии — с 2021 года. Самостоятельно проводим прочностные расчеты в том числе наукоемким методом конечных элементов.

Опыт изготовления оборудования для объектов использования атомной энергии — с 2021 года. Самостоятельно проводим прочностные расчеты в том числе наукоемким методом конечных элементов.

Learn more about the technology

Technology Engineering

Wastewater Treatment Technology

Энергоэффективная технология очистки сточных вод от растворённых в них солей для различных отраслей промышленности. Технология разрабатывается индивидуально под конкретные исходные данные с возможностью получения как жидкого, так и твердого продукта, в том числе товарного.

Learn more about the technology

R&D Center

The

company is actively involved in research activities

All

time we work on improving our existing products and creating new ones, thus

ensure ever-growing technological progress and introducing innovations,

including through grant support of Skolkovo innovation center

Learn

more about R&D Center

20+

Scientific and technical specialists

3

PhD

Alexander Nevolin Head of R&D center

Sergey Styopin Chief technology officer

Partners

50 +

More than 50 Russia's enterprises trust us and choose the Reinnolc engineering and expertise

300 +

units of unique equipment

Consultation

Our

experts are ready to advise you on the issue of interest

Leave your contacts and we will get in touch with you

Founder&CEO