Outcomes of Exerger industrial trial at EVRAZ production site

EXERGER an integrated wastewater treatment technology using a multistage thermal distillation method

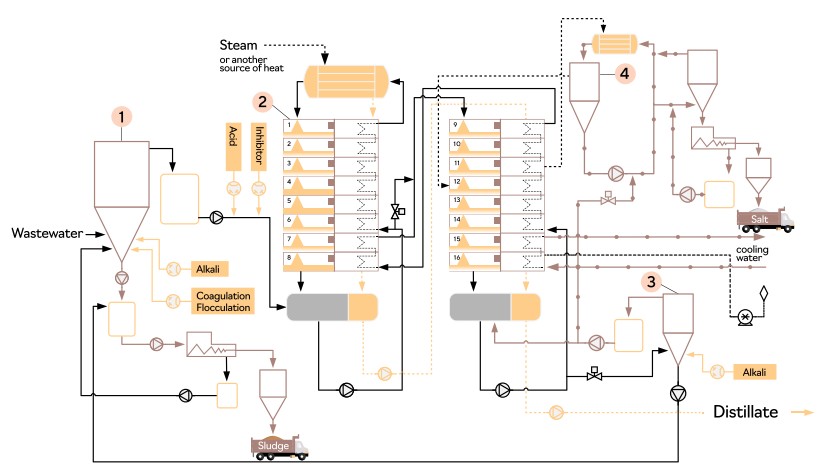

Exerger industrial wastewater treatment technology is based on the thermal distillation method in a highly efficient vertical Multi Stage Flash evaporator.

Exerger ensures the complete treatment of salt-containing wastewater and also provides distilled water, sludge, and crystal salt – the secondary resources for production needs, or marketable products.

- Wastewater treatment to a crystalline residue

- Zero Liquid Discharge

- TDS: 0,5 - 5 ppm

- Hardness: < 0,001 mEq/L

- Silica: < 0,025 ppm

- Iron: < 0,04 ppm

- Oxygen: < 0,02 ppm

Exerger advantages

| Критерий оценки | Выпарная установка Exerger WTU | Классический выпарной аппарат с принуд. циркул. | Обратный осмос | Электродиализ | |

|---|---|---|---|---|---|

| Требования к исходной воде | Предварительное реагентное умягчение | Требуется | Требуется | Требуется | Требуется |

| Подогрев исходной воды | Не требуется | Не требуется | Требуется | Требуется | |

| Взвешенные вещества, органические примеси, нефтепродукты | Допустимо | Допустимо | Не допустимо | Не допустимо | |

| Зависимость от солесодержания | Слабая | Слабая | Сильная | Сильная | |

| Продукты технологии | Деаэрация очищенной воды | ||||

| Степень концентрирования | макс. (>250г/л) | макс. (>250г/л) | 20 г/л | 60 г/л | |

| Полная утилизация жидких стоков | |||||

| Получение кристаллических солей заданного качества или их крепких растворов пригодных для повторного использования или продажи | |||||

| Электропроводность обессоленной воды (без доочистки) | 1-10 мкСм/см | 20-150 мкСм/см | 30-200 мкСм/см | 100-600 мкСм/см | |

| Условия эксплуатации | Зависимость от теплоносителя | Сильная | Очень сильная | Слабая | Слабая |

| Параметры пара | 0,02МПа | 0,04МПа | 0,02МПа | 0,02МПа | |

| Удельный расход пара на 1 м3 стоков, т/м3 | 0,1-0,18 | 0,3-1,1 | 0,02-0,03 | 0,02-0,03 | |

| Удельный расход электроэнергии, кВт*ч/м3 | 4,5-6 | 8-30 | 2-6 | 10-20 | |

| Надежность | Высокая | Высокая | Низкая | Низкая | |

| Возможность безреагентной чистки/промывки | |||||

| Возможность уличного исполнения | |||||

| Регламентный срок службы оборудования |

30 лет

|

30 лет

|

15 лет

|

15 лет

|

|

| Ремонтопригодность | |||||

| Наличие сменных, расходных элементов и периодичность их замены в соответствии с регламентам |

нет

|

нет

|

каждые 2-4 года

|

каждые 2-4 года

|

|

| Зависимость от импортных материалов и компонентов | Низкая | Низкая | Высокая | Средняя |

Exerger WTU energy consumption is 1.8 to 2.5 times lower than equivalents

Applications

Exerger technology is particularly effective in those industries that actively use steam and discharge large volumes of wastewater — for example, in thermal and nuclear power, ferrous and non-ferrous metallurgy, chemical and pulp and paper industries, oil and gas and mining and processing industries.

Na-cationite wastewater (regeneration solutions and wash water)

Exerger technology helps to avoid discharge and get desalinated water, sludge and salt concentrate, used for Na-cationite filters` regeneration. As a result, practically no salt is required for the water softener unit

Chemical desalination wastewater (used regeneration solutions and washing water)

The technology avoids wastewater discharge and allows us to obtain technical salt for our own production needs or commercial use

Blowdown of recirculating water systems

The technology completely prevents wastewater discharge and allows to produce the distillate suitable for higher water quality requirements, or to return the water to the production cycle

Reverse Osmosis brine (concentrate, wash-out solutions)

This is a frequent critical task. The Exerger technology helps to prevent discharge and get the distillate of a higher quality, than that of the Reverse Osmosis permeate

Chemical treatment wastewater and equipment conservation water

The wastewater undergoes neutralization or mutual neutralization (in case of acid and alkaline waste), hardness salts are extracted, evaporated and crystallized. The technology prevents wastewater discharge and allows to obtain technical salt for valuable use for own production needs, or as a marketable product

Biochemical unit wastewater from coking of coal and coke gas cleaning

The biochemical unit cleans the coke chemical production wastewater from organic and non-organic alloys of ammonia, resins and oils, phenols, thiocyanates, cyanides, and ammonium nitrogen and its oxidized forms. Biochemical treatment produces highly mineralized wastewater with an admixture of these substances` degradation products. Exerger further processes the effluent and returns the purified water into the production cycle

Used etching solutions, electrolytes, washing water at the rolling production site

Etching solutions and washing water can be neutralized and the liquid effluents fully evaporated obtaining technical salt as a final product. Electrolytes and washing water can be purified and evaporated to reach a concentration degree suitable for returning to the production cycle

Treatment of washing water used for oil desalination

This type of treatment is complicated by organic impurities in the emulsified state. These admixtures don’t affect the unit’s equipment, which makes the pretreatment process easier and increases the overall reliability

Desalination of water used for washing out salt caverns for gas storage

Desalinated water is used to wash the salt cavern which transforms it into a salt solution as the output. Exerger WTU helps to return the water into the production cycle, clean the water to accelerate the wash-out process, and prevent the wastewater discharge

Quarry, dump and mine waters

Exerger prevents the discharge and allows us to obtain technical salt that can be used for the own production needs or as a product for sale

Mining and processing plants` wastewater

The technology prevents discharge and allows to obtain technical salt that can be used for production needs or as a product for sale

Woodworking industry

Wastewater treatment is complicated by organic impurities in the emulsified state. These admixtures don’t affect the Exerger unit’s equipment, which makes the pretreatment process easier and increases the overall reliability

Sulfate wastewater of the pulp and paper production

Sulfites and sulfates are ions of water-soluble salts difficult to remove from wastewater. Organic impurities in a dissolved or suspended form are an extra complication in the treatment process. Our evaporation technology can extract these salts and prevent the liquid discharge. The sulfates can be returned to the production process

Chemical production wastewater (mineral fertilizers, polymers)

This type of wastewater has a broad variety of compositions. Diluted wastewater with the main substance used in the production technology can be concentrated and returned to the production cycle

Industrial trials of the Exerger technology at EVRAZ production site

In October 2022 ReinnolC implemented the trial project for EVRAZ, a leading steel manufacturing and mining group of companies. The project was aimed at coke gas condensate cleaning after biochemical treatment

— The industrial trial confirmed the Exerger’s efficiency in wastewater treatment after the biological pre-treatment. It cleans 94-99% of wastewater from sulfates, сhlorides, hardness salts and organics. We plan to use the produced distillate for the circulation in water supply cooling systems. The water quality we received from Exerger is substantially higher than the intake water quality. The distillate will increase the efficiency and reliability of the cooling systems.

Outcomes of Exerger industrial trial at EVRAZ production site

ReinnolC develops solutions to reduce water consumption and wastewater discharge and ensures that the wastewater discharge quality complies with environmental regulations of any industry

Request a pilot projectSpecify the specifications of your production in the terms of reference, and we will take care of everything else!